Products

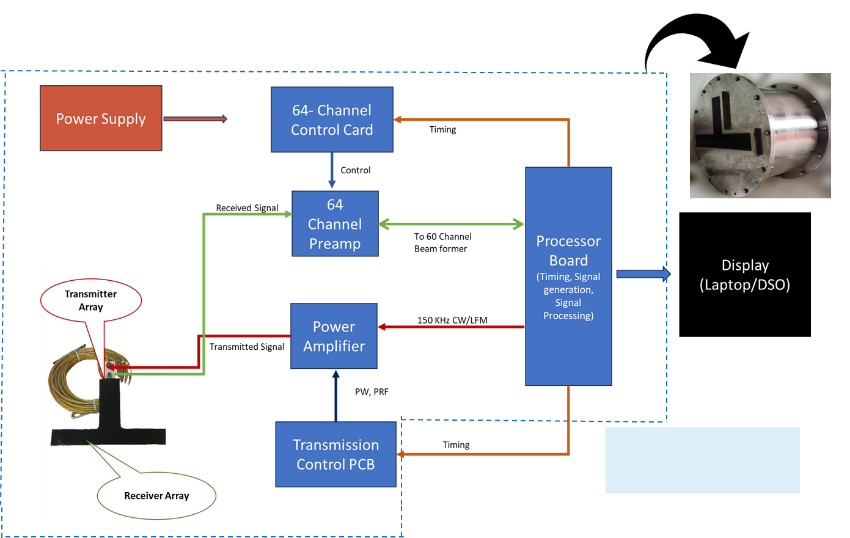

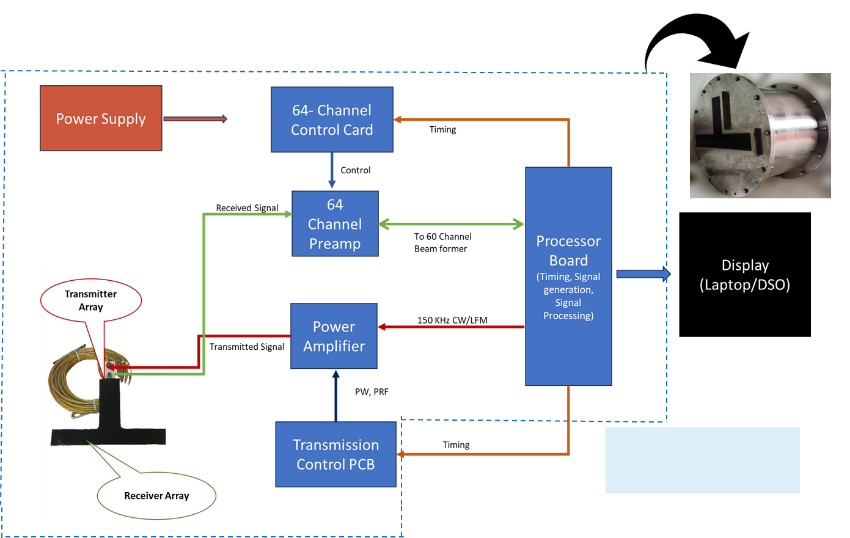

Tarangya-150: 3D Forward-Looking Sonar

Designed for real-time situational awareness and obstacle detection

Operational Role

NKM Info Solutions Pvt. Ltd. is an Indian defence technology company focused on delivering high-reliability, modular and upgradeable systems for underwater and shipborne applications. With strong in-house capabilities across hardware, firmware, software and algorithms, we support the Indian Navy and allied stakeholders in achieving true technological self-reliance.

Our teams possess hands-on experience in design, manufacturing, testing, installation, commissioning and sea trials of complex naval systems.

Architecture & Modularity

The system is built using hardware and software building blocks that enable rapid customization, simplified maintenance and future upgrades without major redesign.

Operator Interface

A modern, intuitive and user-friendly graphical user interface provides operators with real-time data, alerts, system health indicators and control functions. The interface is designed to reduce operator workload and support both local and remote operations

Variants & Growth Options

The core design enables derivation of specialized variants and configurations to meet mission-specific requirements, including future capability enhancements.

Trials & Readiness

The system is engineered for qualification and deployment, with support for integration testing, harbour acceptance trials and sea trials as required by the end user.

Integration & Support

NKM provides complete support for system integration, installation, commissioning, trials and lifecycle maintenance in collaboration with platform integrators and operators.

Tarangya-150: 3D Forward-Looking Sonar

Designed for real-time situational awareness and obstacle detection

Operational Role

NKM Info Solutions Pvt. Ltd. is an Indian defence technology company focused on delivering high-reliability, modular and upgradeable systems for underwater and shipborne applications. With strong in-house capabilities across hardware, firmware, software and algorithms, we support the Indian Navy and allied stakeholders in achieving true technological self-reliance.

Our teams possess hands-on experience in design, manufacturing, testing, installation, commissioning and sea trials of complex naval systems.

Architecture & Modularity

The system is built using hardware and software building blocks that enable rapid customization, simplified maintenance and future upgrades without major redesign.

Operator Interface

A modern, intuitive and user-friendly graphical user interface provides operators with real-time data, alerts, system health indicators and control functions. The interface is designed to reduce operator workload and support both local and remote operations

Variants & Growth Options

The core design enables derivation of specialized variants and configurations to meet mission-specific requirements, including future capability enhancements.

Trials & Readiness

The system is engineered for qualification and deployment, with support for integration testing, harbour acceptance trials and sea trials as required by the end user.

Integration & Support

NKM provides complete support for system integration, installation, commissioning, trials and lifecycle maintenance in collaboration with platform integrators and operators.

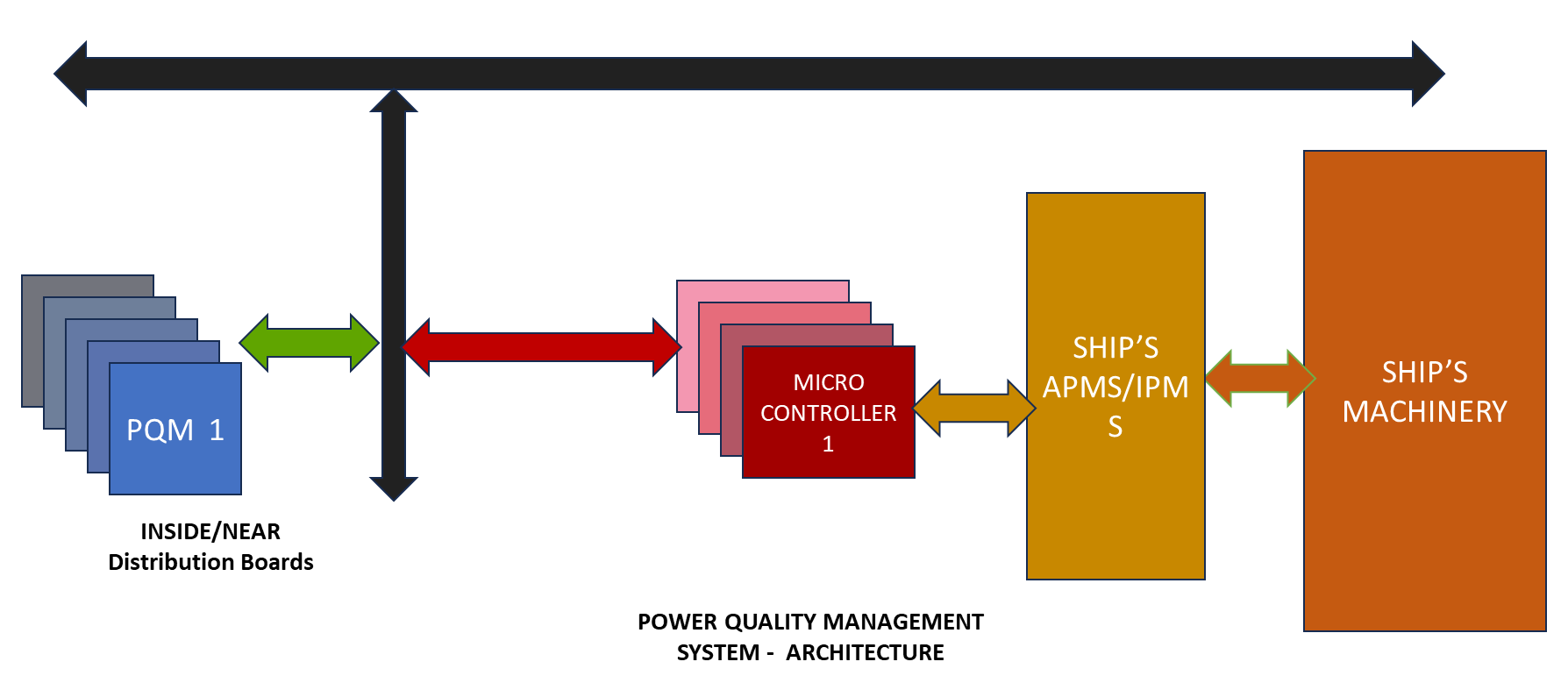

Power Quality Management System (PQMS)

PQMS has a number of Power Quality Modules (PQMs) at its heart and the system is intended to function as the “on-line monitoring device” to continuously detect parameters that are “deviations from NORMAL”, with ultimate aim to protect connected sensitive equipment.

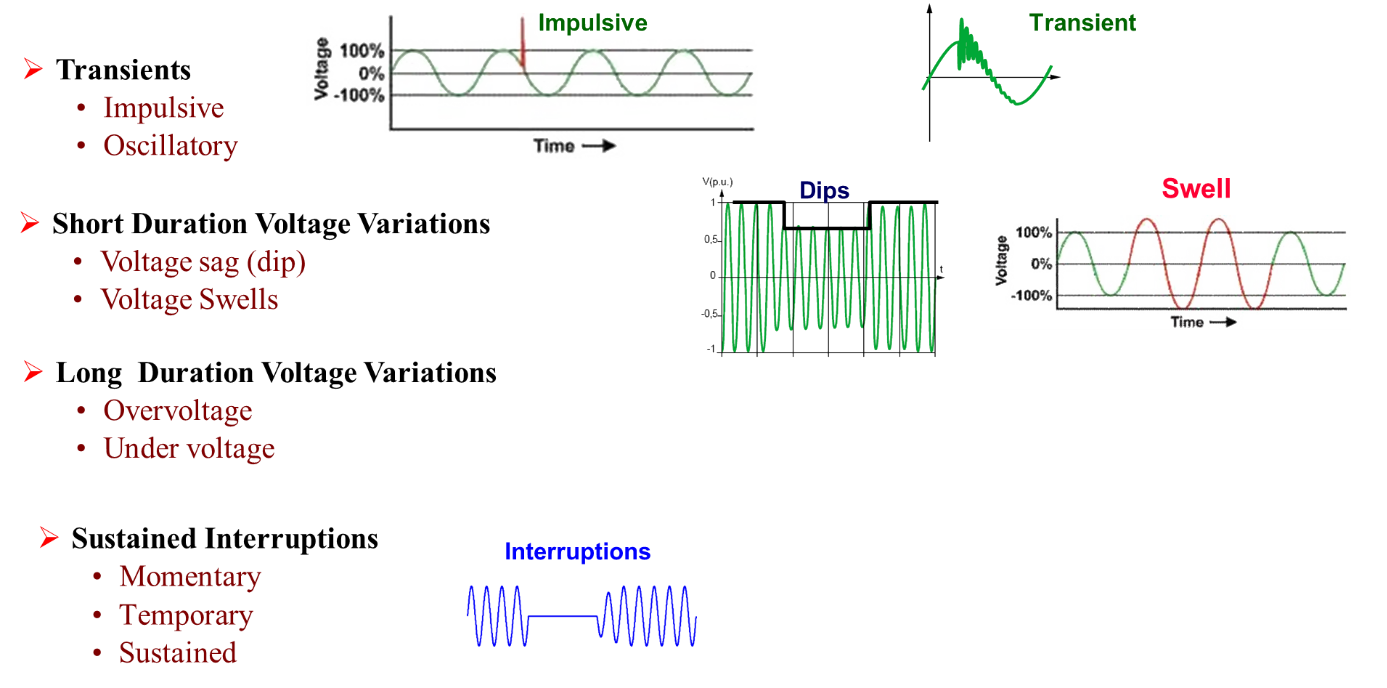

General Classes of Power Quality Problems

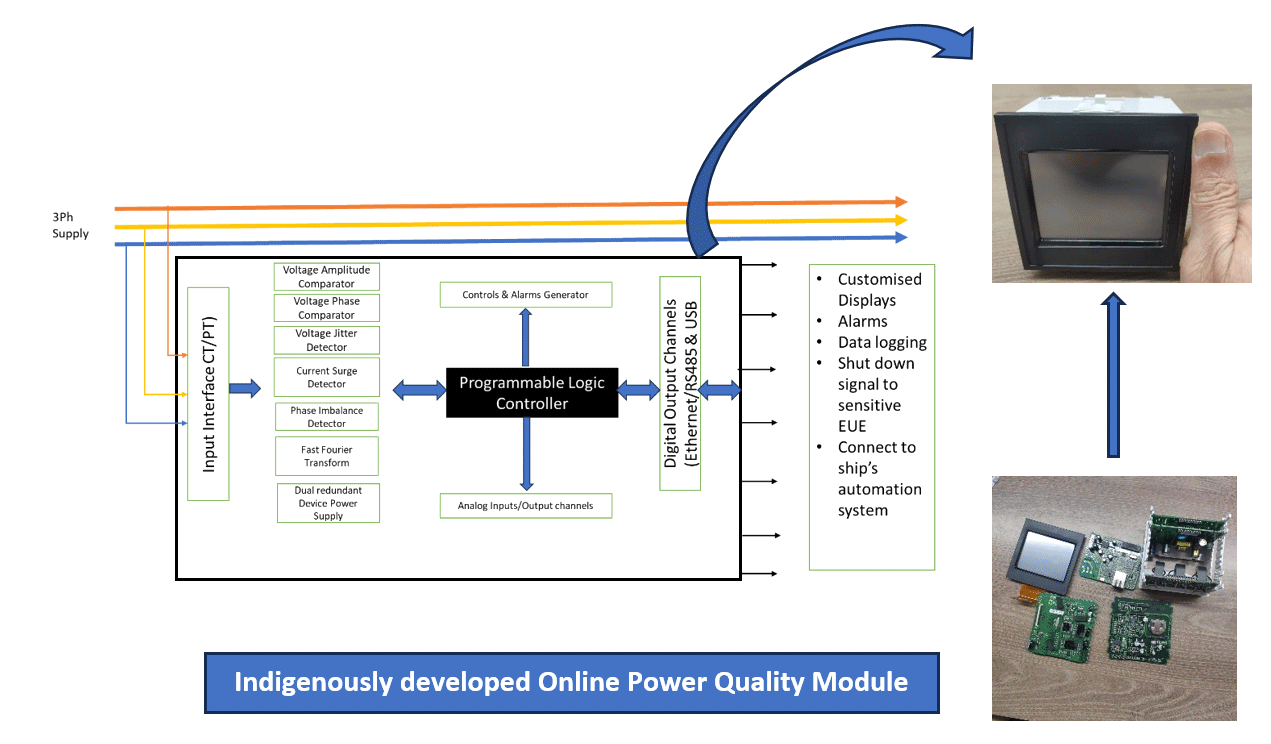

Indigenously developed Online Power Quality Module

Central Processing & Decision Support Module (Workstation)

Operational Overview of PQMS

PQMS continuously monitors the input power supply using a versatile Power Quality module to capture, record and display even the minutest of the variations in power supply variations in real-time, compare with define thresholds raise audio visual alarms to caution the watchkeeper of power quality aberrations and even force shut down power supply to the connected sensitive equipment with the aim to protect it from an impending failure. The system in conjunction with start/stop inputs from onboard machinery carries out causative analysis and with embedded AI algorithms can suggest remedial measures to prevent occurrence of dangerously high-power quality aberrations. Processed information compiled across all PQMs is transferred to shore-based Data Lake, where similar inputs from other ships can be compiled/analysed for meaningful conclusions.

Architecture & Modularity

Online Power Quality Module is the heart of the system, around which is the complete management system is built. The PQM is connected to a high-end Workstation through a serial Bus. The Workstation is either interfaced with platform’s Auxiliary Control System (ACS) that controls start/stop of all major electrical machinery) or, in the absence of ACS, connected to the electrical machinery through a number of microcontroller-based interfaces. The software, designed in three layers is highly modular, upgradable and configurable comprising of

M

• Embedded software that resides within the PQM and controls its internal functioning

• System software that resides in the Workstation and carries out reformatting of inputs from PQM, analysis, recording, event generation etc.

• Application software, resides in the Workstation and provides the system level capability

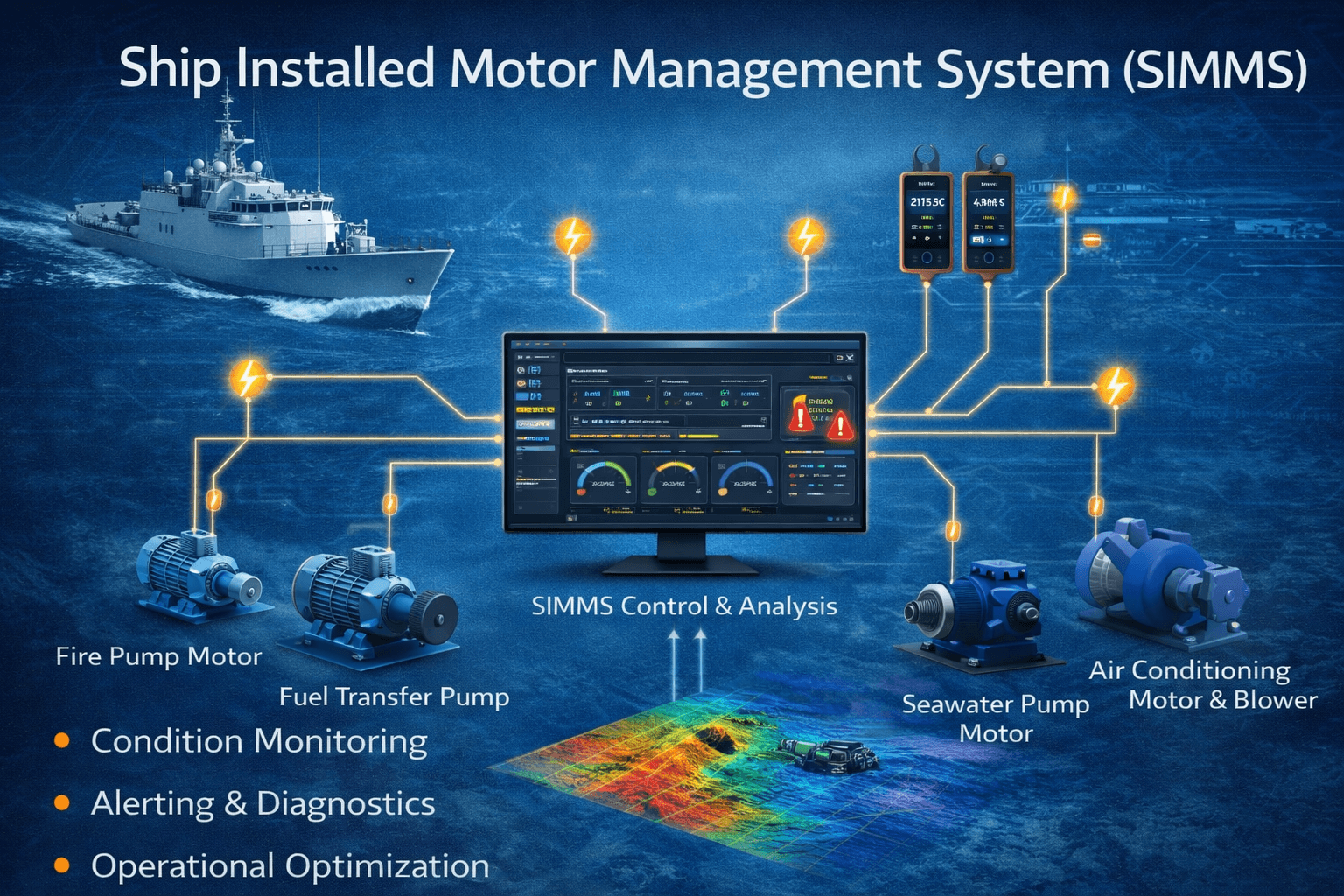

Ship Installed Motor Management System (SIMMS)

Ship-Installed Motor Management System (SIMMS) capable of predicting potential failures of connected motors by continuously monitoring key electrical parameters during both the starting and running phases of operation. The system employs Artificial Intelligence (AI) and Machine Learning (ML) algorithms to analyze the acquired data, with the accuracy of failure prediction improving progressively as more operational data is collected and processed

Product Overview

SIMMS is designed to continuously monitor the starting and running (steady-satet) currents of induction motors. When analyzed in both the time and frequency domains, this current signature serves as a powerful diagnostic tool, offering an indirect yet accurate reflection of the condition of the motor, the connected load, and the coupling between them. Additional parameters, such as vibration levels and winding temperatures measured locally at the motor, further enrich the diagnostic dataset. When these parameters are continuously monitored and compared against established baseline (ideal) characteristics, it becomes feasible to detect deviations and trends indicative of impending or imminent failures. By leveraging this multi-parameter monitoring approach, integrated with intelligent analytics, the operational health of induction motors can be effectively assessed, and early warnings of potential failures can be reliably generated.

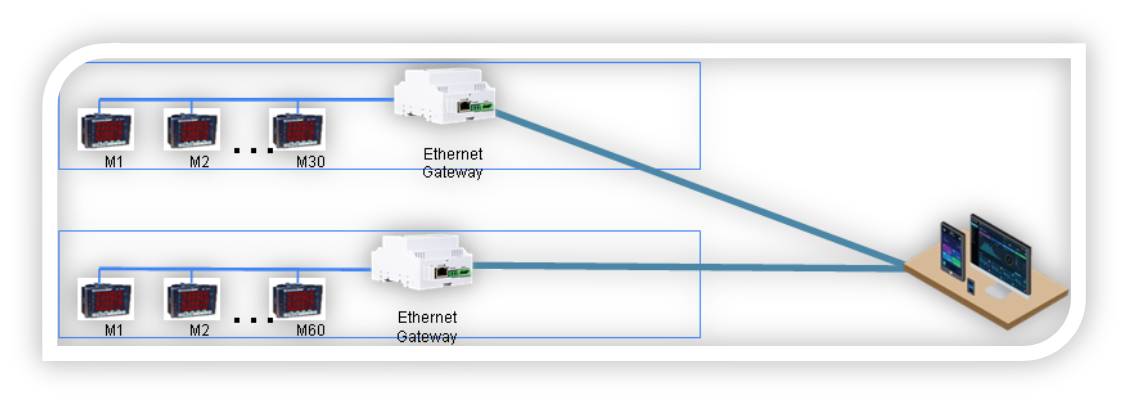

Network Architecture of SIMMS

Operational View of SIMMS

While the SIMMS is designed to provide reliable and progressively improving insights into impending motor failures based solely on electrical parameters, its performance and diagnostic accuracy can be significantly enhanced through the integration of additional sensory inputs. Specifically, parameters such as motor winding temperature and vibration data, if available locally or through existing shipboard systems, can be seamlessly incorporated into the SIMMS architecture. These additional inputs will provide multidimensional insights into motor health, enabling improved differentiation between electrical and mechanical faults, timely detection of thermal overloads or bearing-related issues, enhanced AI/ML model performance through richer data sets.

Architecture & Modularity

SIMMS is designed using the Energy Management Module (EMM) as the basic building block, for each motor. Up to thirty motors in vicinity can be connected on a single ethernet network and thereafter connected to the Motor Management Module (High-end Workstation) via Ethernet Gateway. Up to ten such gateways (max 300 motors) can therefore be hosted on SIMMS. The software is also highly modular and upgradable.